100% REGENERATED YARNS AND TEXTILES

ISO 14021:2021 COMPLIANT

LCA Tested (Life Cycle Assestment Report)

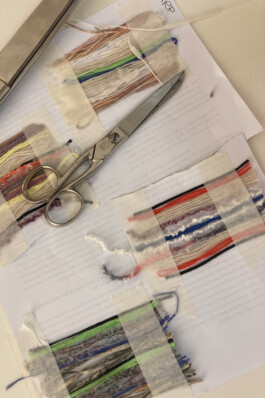

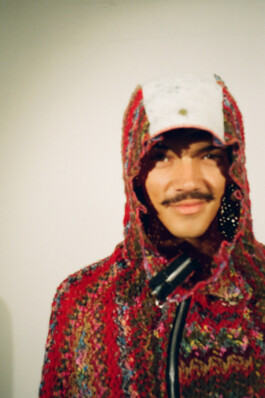

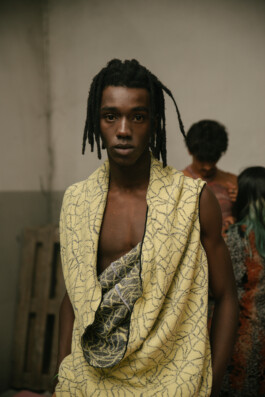

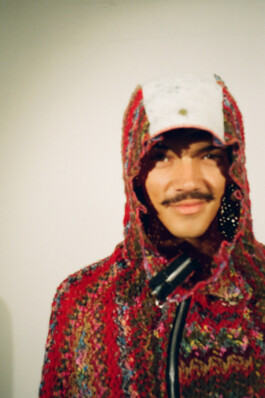

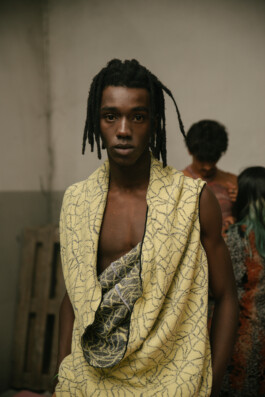

In an open dialogue with “true” Made in Italy, and through a series of semi-artisanal techniques, mostly developed with 80s mechanical machinery,

Vitelli has developed its own signature regenerative process –Doomboh®– gradually putting together a new fashion vocabulary, and a new idea of sustainable luxury.

100% reclaimed yarn is “felted” with a special needle-punching technique. This regenerative practice allows us to create rolls of hybrid fabric with a one-of-a-kind look that has now become an integral part of the Vitelli offering.

Needle-punching reclaimed yarn means: collecting leftover/deadstock/end-of-cones yarn from northern-Italy; preparing threads compositions; punching such compositions with bars of needles, on a special 80s mechanical machine we saved from extinction.

Each season we reclaim approximately 200kg of yarn for the prototyping and sampling phase, and over 800kg for the production phase.

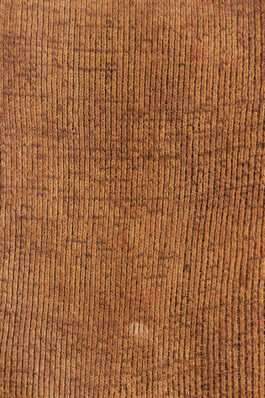

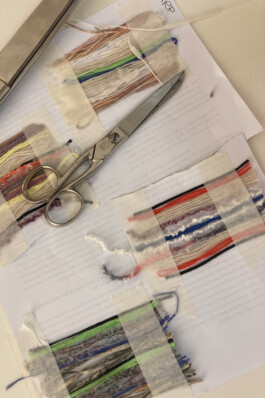

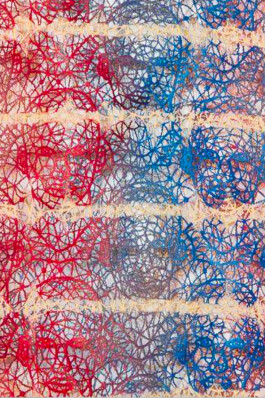

DOOMBOH® Warp is a hybrid-textile line where 100% reclaimed yarn gets woven out of original 70s-made mechanical machines.

Doomboh Warp “frames” are fabricated by loading variable threads on 70s mechanical weaving machines, regardless of the different gauges and composition, in a sort of linear patchworking of waste yarn.

Warp hybrid textiles can be then offered in different gauges and multiple color combinations.

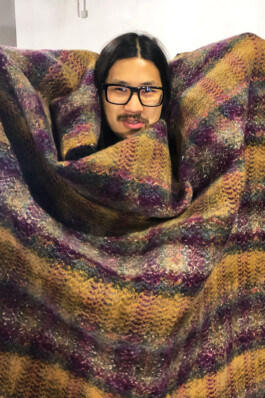

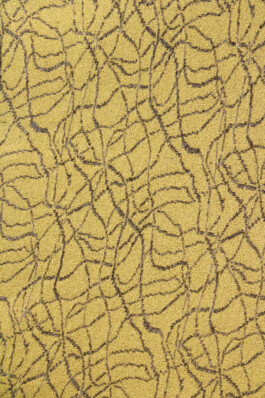

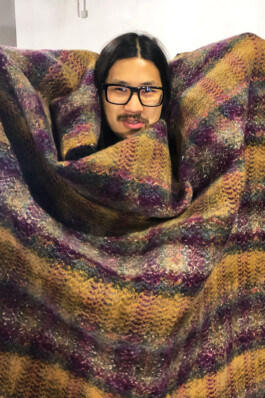

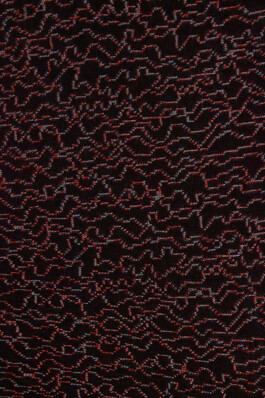

DOOMBOH® Knit is Vitelli’s ultimate experimentation on industrial knitwear.

Fabrics are knitted by original 1980’s “Stoll” linear knitting machines, re-programmed to create intricate jacquard panels from our seasonally reclaimed yarns.

With Doomboh® Knits we look for hybrid stitching that recalls the classic “warp&weft”textile. The resulting fabrics maintain the fluidity of knitwear with a woven look.

The panels are cut-and-sewn as “jersey” textile, bridging knitwear and tailoring in our rich and visually impactful “prima-linea” collections.

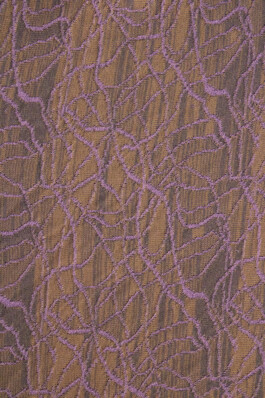

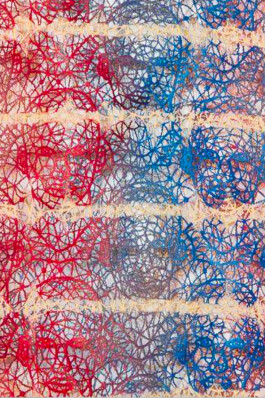

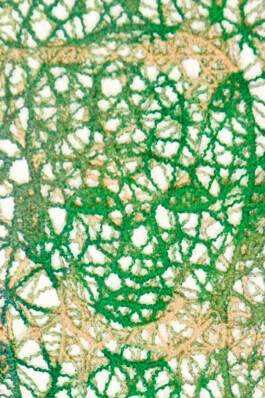

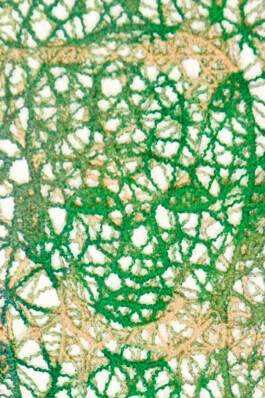

DOOMBOH® Lace takes yarn regeneration to the highest level through Italian embroidery excellence.

Once again the Vitelli team scouts the most hidden deadstock-yarn gems in the neighborhood, and works tightly with Lombardy best embroidery labs for the development of regenerated fabric cloths made of laces, macramé and mixed-technique all-over embroidery, with exclusive motifs.

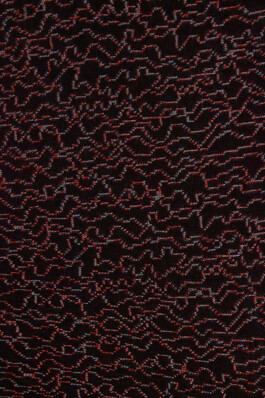

A certified regenerative technique, based on needle-punching on deadstock denim.

Vitelli Jeans is our new venture into the realm of denim... in our own fabrication practice. Instead of washing raw denim, we needle-punch deadstock silk and knits onto deadstock denim panels, creating a delicate ripples effect making each garment unique.

info@vitelli.earth

100% REGENERATED YARNS AND TEXTILES

ISO 14021:2021 COMPLIANT

LCA Tested (Life Cycle Assestment Report)

In an open dialogue with “true” Made in Italy, and through a series of semi-artisanal techniques, mostly developed with 80s mechanical machinery,

Vitelli has developed its own signature regenerative process –Doomboh®– gradually putting together a new fashion vocabulary, and a new idea of sustainable luxury.

100% reclaimed yarn is “felted” with a special needle-punching technique. This regenerative practice allows us to create rolls of hybrid fabric with a one-of-a-kind look that has now become an integral part of the Vitelli offering.

Needle-punching reclaimed yarn means: collecting leftover/deadstock/end-of-cones yarn from northern-Italy; preparing threads compositions; punching such compositions with bars of needles, on a special 80s mechanical machine we saved from extinction.

Each season we reclaim approximately 200kg of yarn for the prototyping and sampling phase, and over 800kg for the production phase.

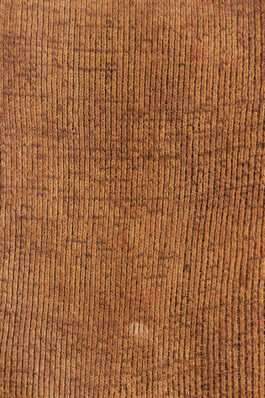

DOOMBOH® Warp is a hybrid-textile line where 100% reclaimed yarn gets woven out of original 70s-made mechanical machines.

Doomboh Warp “frames” are fabricated by loading variable threads on 70s mechanical weaving machines, regardless of the different gauges and composition, in a sort of linear patchworking of waste yarn.

Warp hybrid textiles can be then offered in different gauges and multiple color combinations.

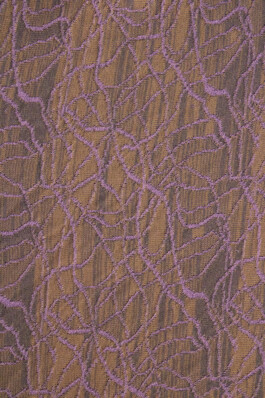

DOOMBOH® Knit is Vitelli’s ultimate experimentation on industrial knitwear.

Fabrics are knitted by original 1980’s “Stoll” linear knitting machines, re-programmed to create intricate jacquard panels from our seasonally reclaimed yarns.

With Doomboh® Knits we look for hybrid stitching that recalls the classic “warp&weft”textile. The resulting fabrics maintain the fluidity of knitwear with a woven look.

The panels are cut-and-sewn as “jersey” textile, bridging knitwear and tailoring in our rich and visually impactful “prima-linea” collections.

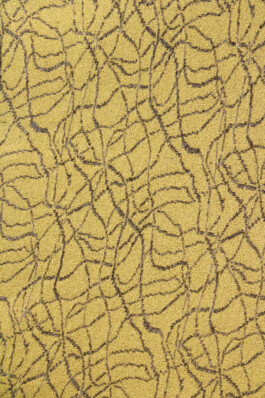

DOOMBOH® Lace takes yarn regeneration to the highest level through Italian embroidery excellence.

Once again the Vitelli team scouts the most hidden deadstock-yarn gems in the neighborhood, and works tightly with Lombardy best embroidery labs for the development of regenerated fabric cloths made of laces, macramé and mixed-technique all-over embroidery, with exclusive motifs.

A certified regenerative technique, based on needle-punching on deadstock denim.

Vitelli Jeans is our new venture into the realm of denim... in our own fabrication practice. Instead of washing raw denim, we needle-punch deadstock silk and knits onto deadstock denim panels, creating a delicate ripples effect making each garment unique.

info@vitelli.earth

Cookie Policy, Terms & Conditions, Refunds & Returns Policy — La Fazenda Italia S.R.L.